- Measuring Systems

- Marking Solutions

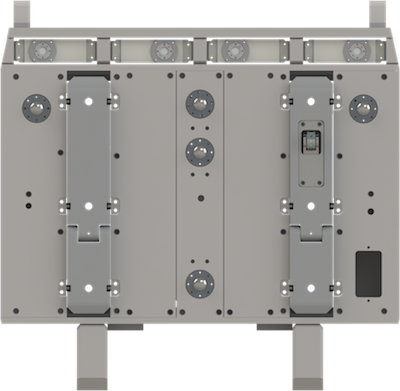

Roll Checker

Casting Line Monitoring System

Introduction

OSN-9000 is a modern measuring system for strand conditions monitoring in slab continuous casting lines. Thanks to high accurate sensors, modern signal processors and user friendly software as well as rugged design for mechanical parts withstanding in harsh strand conditions with minimum maintenance and recalibration requirements, its functionalities, especially “On-Line” feature, are unique.

|

|

Application

OSN-9000 is an automatic self-powered and heavy duty machine that connects to the dummy bar chain in the dummy bar head while the continuous casting line is stopped for maintenance. It is designed to measure casting line parameters and peripheral conditions such as roll gap, roll bending, roll rotation, cooling water spray and roll alignment in harsh environment to ensure the final product meets all the standard characteristics in surface quality and sizes. Special software undertakes to display the final result of all parameters in graph and numerical data, coherently, on separate desktop, lap top or hand held computers. The maintenance experts survey the graphs and different parameters recorded by system and if any disorientation is found in caster strand, it should be repaired or adjusted.

Features

- User calibration possibility

- Sensors and all equipment tolerate against unwanted wear and harsh conditions

- Proper sealing for electronic enclosure

- Water proof cable and connectors withstands sulfated

- Stainless steel electronic enclosure, connectors and sensors

- Custom design systems for different casters

For complete information, please contact us.